Bespoke Angle Bracket: Custom Solutions for Structural Support

What is a Bespoke Angle Bracket?

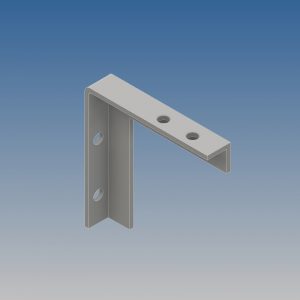

A bespoke angle bracket is a custom-made, L-shaped metal support designed to meet specific project requirements. Unlike standard brackets, bespoke angle brackets are tailored to the unique dimensions and load capacities of your project, offering personalized solutions for a variety of industrial, construction, and engineering applications. These brackets are ideal for providing structural support, reinforcement, and secure connections between components, ensuring the stability and longevity of installations.

Whether you’re working on steelwork, furniture manufacturing, or architectural projects, bespoke angle brackets offer the flexibility and strength needed to achieve precise, customized results.

Key Features of Bespoke Angle Brackets

1. Custom Dimensions

One of the standout features of bespoke angle brackets is their ability to be manufactured to exact specifications. You can choose the angle, length, thickness, and hole placement, ensuring that the bracket fits seamlessly into your design. This customization allows you to tackle complex and unique installations where standard brackets may not suffice.

2. Material Options

Bespoke angle brackets can be fabricated from a variety of materials to suit the requirements of your project. Common materials include:

- Mild Steel

- Stainless Steel for corrosion resistance

- Aluminium for lightweight applications

- Galvanized Steel for outdoor durability

Each material has its advantages, and selecting the right one ensures that your bespoke angle bracket performs optimally under different environmental conditions.

3. Load-Bearing Capacity

Bespoke angle brackets are designed to handle heavy loads, making them suitable for structural applications in construction, HVAC, and mechanical systems. Depending on the project’s demands, these brackets can be engineered to support substantial weight, providing robust and reliable support for critical installations.

4. Corrosion-Resistant Finishes

For outdoor or moisture-exposed environments, bespoke angle brackets can be finished with galvanization, powder coating, or zinc plating. These finishes enhance the bracket’s durability, ensuring it resists corrosion and maintains its strength over time.

Common Applications for Bespoke Angle Brackets

1. Construction and Building Support

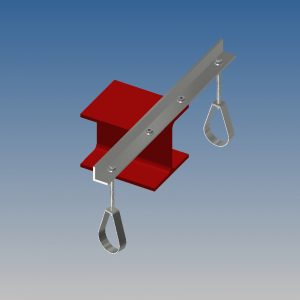

In construction, bespoke angle brackets are used to support various structural elements such as steel beams, wooden frameworks, and concrete anchors. Their customized dimensions make them ideal for providing reinforcement where traditional brackets wouldn’t be compatible. They ensure the stability of walls, ceilings, and floor joists, particularly in projects that involve complex or irregular architectural designs.

2. Mechanical and Electrical Installations

Bespoke brackets are frequently used in mechanical systems for mounting HVAC units, ductwork, and heavy machinery. In electrical installations, they help secure cable trays, conduits, and switchgear to the structural framework of a building. The ability to tailor the size and strength of the bracket ensures that these critical components are held securely in place.

3. Bespoke Furniture and Joinery

For furniture designers and manufacturers, custom angle brackets offer a way to create unique, high-quality pieces. Whether it’s for custom shelving, cabinetry, or table frames, bespoke brackets provide both aesthetic appeal and structural integrity. They can be designed to blend seamlessly into the furniture’s style, while still offering the necessary support.

4. Architectural and Engineering Projects

Architects and engineers often require custom brackets for specialized builds, particularly in bridge construction, façade support, and other high-load applications. Bespoke angle brackets offer precision and strength in these critical areas, ensuring that the design vision is brought to life without compromising on safety or durability.

Benefits of Using Bespoke Angle Brackets

1. Perfect Fit for Complex Designs

When off-the-shelf products don’t meet your specific needs, bespoke angle brackets provide the perfect solution. With fully customizable options, you can design the exact bracket required for your project, ensuring a perfect fit for complex geometries and irregular spaces.

2. Enhanced Structural Integrity

Bespoke brackets are engineered to provide superior strength, offering enhanced load-bearing capacity and structural support. This makes them ideal for high-demand projects, such as bridge construction, heavy machinery support, and infrastructure development.

3. Cost-Effective Customization

While custom-made brackets may seem more expensive upfront, their ability to solve specific design challenges often reduces overall costs by avoiding the need for extra labor, modifications, or additional support structures. The time saved by using a bracket that fits perfectly into your design can offset the initial expense.

4. Adaptability Across Multiple Industries

Because they are customizable, bespoke angle brackets can be adapted for use in a wide variety of industries. From heavy industry and construction to home improvement and furniture design, these brackets provide versatile support for projects of all sizes and scopes.

Manufacturing Process of Bespoke Angle Brackets

1. Design and Engineering

The process of creating a bespoke angle bracket starts with detailed discussions regarding the project’s specific requirements. Engineers work with you to understand your needs, including load requirements, environmental conditions, and material preferences. CAD (Computer-Aided Design) is often used to ensure precise measurements and dimensions.

2. Material Selection

Once the design is finalized, the appropriate material is selected based on the bracket’s application. For example, stainless steel might be chosen for high-corrosion environments, while mild steel could be used for indoor applications requiring significant load-bearing strength.

3. Fabrication

The bracket is then fabricated using a combination of cutting, bending, and welding techniques. Hole drilling or punching can be added based on the bracket’s intended use, allowing for easier installation and component attachment.

4. Finishing and Quality Control

After fabrication, the brackets are finished with galvanization, painting, or other coatings to ensure they withstand environmental conditions. Rigorous quality control checks ensure that the brackets meet all specifications and are ready for installation.

Conclusion

Bespoke angle brackets offer a highly customizable, durable, and cost-effective solution for various structural and industrial applications. Whether you’re building complex architectural designs, supporting heavy machinery, or reinforcing construction frameworks, these brackets provide the tailored strength and precision required for any project. With the ability to choose your bracket’s dimensions, material, and finish, you can ensure the perfect fit and long-lasting performance.

Showing all 2 results

Showing all 2 results