Beam Clamps for Strut: Secure and Efficient Steel Beam Connections

Overview of Beam Clamps for Strut

Beam clamps for strut are highly efficient devices designed to attach strut channels to structural steel beams without the need for drilling or welding. These clamps are essential for supporting various building systems such as pipework, HVAC systems, electrical conduits, and cable trays. By clamping directly onto the beam flange, beam clamps provide a secure and stable connection, enabling quick installations in both industrial and commercial projects. They offer a practical, cost-effective, and non-destructive solution for connecting components to steel beams.

Whether used for lifting, support, or rigging, beam clamps for strut are the go-to choice for contractors looking for reliability and ease of installation.

Key Features of Beam Clamps for Strut

1. No Drilling or Welding Required

One of the main benefits of using beam clamps is the elimination of the need for drilling or welding into steel beams. This not only preserves the structural integrity of the beam but also speeds up installation times, making it a more efficient method for securing strut channels and other fixtures.

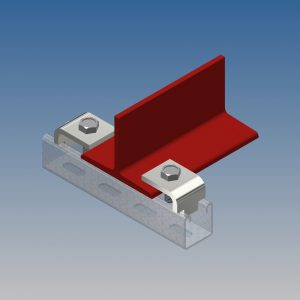

2. Secure and Adjustable Connections

Beam clamps for strut provide a secure grip onto I-beams or other structural supports, allowing for strong and reliable connections. They are adjustable and can be repositioned easily, making them flexible for various installation requirements.

3. Wide Range of Applications

Beam clamps are used in a variety of applications, from suspending pipe systems and cable management trays to mounting HVAC units and electrical systems. They can handle heavy loads and are perfect for overhead installations where stability and safety are critical.

4. Corrosion-Resistant Finishes

Many beam clamps are available with corrosion-resistant finishes, such as hot-dip galvanization or zinc plating. This protects them from rust and degradation, making them suitable for both indoor and outdoor environments, including those with exposure to harsh weather conditions.

5. Compatibility with Strut Channels

These clamps are compatible with a wide range of strut channels, including the standard 41 x 21 mm and 41 x 41 mm sizes. This versatility makes them ideal for connecting multiple components across different systems.

Benefits of Beam Clamps for Strut

1. Quick and Easy Installation

The no-drill and no-weld design significantly reduces the time and complexity of installations. With beam clamps, contractors can quickly attach strut channels to beams without needing specialized tools or techniques. This results in less downtime on projects and lower labor costs.

2. Preserves Beam Integrity

Since beam clamps do not require any permanent alterations to the steel beams, they maintain the integrity of the structure. This makes them an excellent option for projects where the beams may need to be repurposed or reconfigured later on.

3. Flexible for Temporary or Permanent Use

Because they are non-invasive, beam clamps can be easily removed or repositioned if the installation needs to be adjusted or relocated. This makes them suitable for both temporary setups (such as event rigging) and permanent installations (such as pipework or HVAC systems).

4. Load Capacity and Durability

Beam clamps are designed to handle heavy loads, making them ideal for industrial settings where equipment or systems need to be supported overhead. With options for different load capacities, they can be selected based on the specific requirements of the project.

5. Cost-Effective Solution

By eliminating the need for labor-intensive procedures like drilling and welding, beam clamps offer a cost-effective solution for connecting components to beams. They are affordable, durable, and help streamline the overall installation process.

Applications of Beam Clamps for Strut

1. Pipe and Duct Support

In mechanical installations, beam clamps are commonly used to suspend pipework or ducting systems from structural beams. This allows for the safe and organized routing of water, gas, or air flow through buildings, ensuring reliable system operation.

2. Cable Management Systems

For electrical and data cabling installations, beam clamps offer a reliable way to secure cable trays and cable management systems. The strut channels attached to the beam support and organize cables, reducing clutter and enhancing safety.

3. HVAC Unit Mounting

Large HVAC units or other mechanical equipment can be securely mounted using beam clamps. By clamping strut channels to the I-beam, contractors create a stable and supportive framework for holding heavy HVAC components in place.

4. Lighting and Equipment Suspension

In industrial and commercial spaces, beam clamps can be used to suspend lighting fixtures or other equipment from overhead beams. They provide a versatile platform for securely mounting and adjusting the height and position of various components.

Types of Beam Clamps for Strut

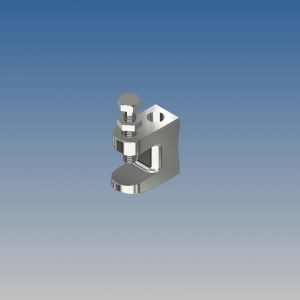

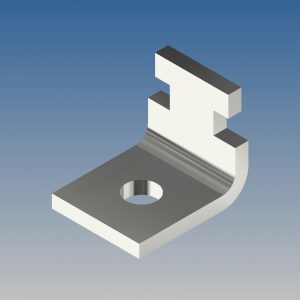

1. Fixed Beam Clamps

These are designed for fixed-position applications where the strut channel or fixture needs to remain in one place. They offer strong, stable support and are ideal for permanent installations.

2. Adjustable Beam Clamps

Adjustable beam clamps allow for greater flexibility during installation. They can be repositioned along the beam to adjust the location of the strut channel, making them ideal for projects that may require adjustments over time.

3. Pitched Beam Clamps

Specifically designed for use on sloped or pitched beams, these clamps provide secure attachments even in complex structural configurations. They are commonly used in spaces with angled ceilings or unconventional beam orientations.

Beam Clamp Installation Guide

Step 1: Choose the Right Clamp

Select a beam clamp that is appropriate for your specific application. Ensure the clamp is compatible with both the beam size and the strut channel or fixture you plan to install.

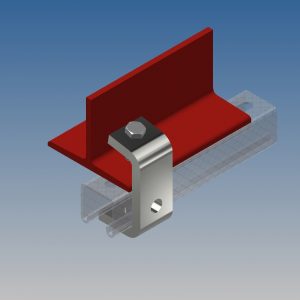

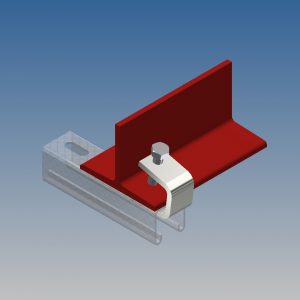

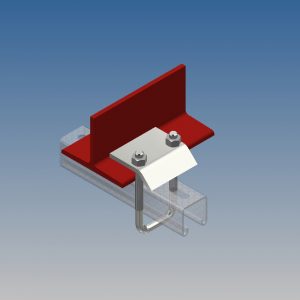

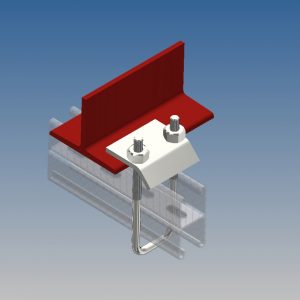

Step 2: Position the Clamp on the Beam

Position the clamp on the I-beam flange where you want to attach the strut channel or fixture. Make sure it is centered and aligned correctly to provide optimal support.

Step 3: Attach the Strut Channel

Insert the strut channel into the clamp, ensuring it fits securely. Use appropriate hardware (e.g., bolts or U-bolts) to secure the channel in place.

Step 4: Tighten and Secure the Clamp

Tighten the clamp bolts or screws to securely fasten it to the beam. Double-check that the strut channel or fixture is stable and properly aligned before completing the installation.

Conclusion

Beam clamps for strut offer a fast, efficient, and non-invasive solution for attaching strut channels to structural beams. By eliminating the need for drilling and welding, these clamps save time and labor while preserving the structural integrity of the beams. They are versatile, adjustable, and suitable for a wide range of applications, from supporting pipework and cable trays to suspending HVAC systems and lighting fixtures. With corrosion-resistant finishes and a variety of configurations, beam clamps are a reliable choice for both indoor and outdoor installations.

Showing all 12 results

-

Drilled Beam Clamps

£1.00 Select options -

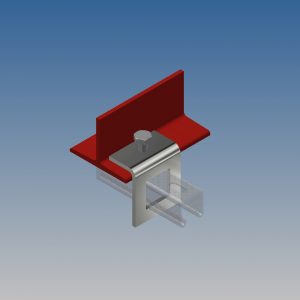

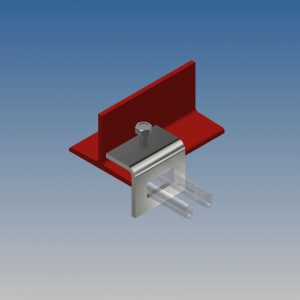

P1271 Tapped Channel Beam Clamps Large

£0.01 Add to quote -

P1272 Tapped Channel Beam Clamps Mini

£0.01 Add to quote -

P1386 Channel Beam Clamps

£0.01 Add to quote -

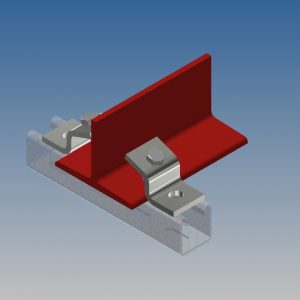

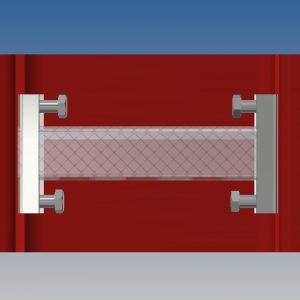

P1796 41×41 Window Bracket

£0.01 Add to quote -

P1796A 41×21 Window Bracket

£0.01 Add to quote -

P1796B 41×82 Window Bracket

£0.01 Add to quote -

P1983 Tapped Z Beam Clamps

£0.01 Add to quote -

P2489 Heavy Duty Tapped Beam Clamps

£0.01 Add to quote -

P2785 Single Channel U Bolt Assembly

£0.01 Add to quote -

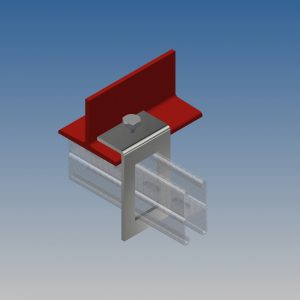

P2786 Double Channel U Bolt Assembly

£0.01 Add to quote -

P3087 Internal Beam Clamps

£0.01 Add to quote

Showing all 12 results