Beam Clamp and Girder Clamp: Secure and Flexible Suspension Solutions

What is a Beam Clamp or Girder Clamp?

A Beam Clamp (also known as a Girder Clamp) is a versatile and essential tool used to suspend or secure various fixtures, threaded rods, electrical wiring, and other hardware onto beam flanges. These clamps provide a secure fixing solution without the need for welding or drilling, making them a time-efficient and cost-effective choice for a wide range of construction and industrial applications.

Whether used to support pipework, suspend electrical conduits, or secure HVAC systems, Beam Clamps offer a reliable method of attaching hardware to structural beams, I-beams, and girders without compromising the structural integrity of the beam itself.

Key Features of Beam and Girder Clamps

1. No Welding or Drilling Required

One of the biggest advantages of using a Beam Clamp is the ability to securely fix components to beams without the need for welding or drilling. This not only reduces the installation time but also ensures that the integrity of the beam is maintained, avoiding potential weakening caused by holes or heat from welding.

2. Secure Fixing for Heavy Loads

Beam clamps are designed to support heavy loads, making them ideal for industrial and construction environments. They are often used to suspend threaded rods, which in turn support HVAC systems, pipework, cable trays, or other mechanical components. The robust design of beam clamps ensures that once installed, they provide a strong and stable connection.

3. Compatibility with Pitched Beams

Special types of beam clamps are available for securing onto pitched beams. These clamps are designed to accommodate the angle of the beam while still offering a firm grip, ensuring that fixtures remain securely attached even on sloped or angled surfaces.

4. Wide Range of Applications

From electrical installations to HVAC systems and pipework, beam clamps are used across many industries. Their ability to attach various components without modifying the structural beam makes them invaluable for contractors, engineers, and construction professionals.

Technical Specifications of Beam Clamps

- Materials: Typically made from steel or malleable iron for maximum durability

- Finishes: Available in hot-dip galvanized, zinc-plated, or self-colour finishes to resist corrosion

- Sizes: Suitable for different beam flange widths, depending on load requirements

- Load Capacity: Engineered to support substantial loads, typically ranging from 100kg to over 500kg, depending on the specific clamp

- Adjustment Options: Many clamps feature adjustable designs to fit various beam sizes and shapes

Standard Beam Clamp Dimensions

- Flange Width: Available for beam flanges ranging from 6mm to 50mm or more

- Threaded Rod Compatibility: Common sizes include M8, M10, M12, and M16, ensuring compatibility with industry-standard rods

- Load Rating: Load ratings can vary, with heavy-duty options available for high-stress applications

How Beam Clamps Work

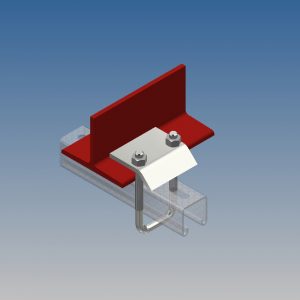

Beam Clamps function by clamping securely to the flange of an I-beam or girder. Once installed, the clamp provides a stable anchor point to suspend hardware, piping, or electrical equipment. The clamp is tightened onto the flange using bolts, and once in place, it holds the fixture firmly without the need for permanent modifications, such as welding or drilling.

Applications of Beam and Girder Clamps

1. Pipe Support Systems

Beam clamps are widely used to support pipe hangers and threaded rods in plumbing, fire protection, and mechanical piping installations. By attaching the clamp to the flange of an I-beam, pipes can be suspended securely overhead, allowing for efficient space management and reducing ground-level obstructions.

2. Electrical Installations

In electrical installations, beam clamps provide a stable anchor point for suspending cable trays, conduits, and electrical junction boxes. These clamps can also be used to secure heavy-duty electrical wiring, ensuring that the installation is safe, tidy, and complies with industry standards.

3. HVAC Systems

Beam clamps are crucial in supporting HVAC systems, which often require the suspension of ducts, air-handling units, and other mechanical components from ceilings or beams. Their ease of installation and secure fixing capabilities make them a go-to solution for HVAC contractors.

4. Lighting Systems

For overhead lighting systems, beam clamps can suspend light fixtures or electrical junction boxes from I-beams in industrial facilities, warehouses, or commercial spaces. They offer a reliable solution for hanging lights without damaging the structural steel.

5. Temporary Fixing Solutions

Since beam clamps do not require permanent alterations to the structure, they are ideal for temporary installations. Whether used for events, temporary power lines, or scaffolding support, beam clamps can be quickly installed and removed as needed.

Benefits of Using Beam and Girder Clamps

1. Fast and Efficient Installation

Beam clamps can be quickly installed without the need for complex equipment or procedures. By eliminating the need for welding or drilling, contractors can save time on-site, reducing labour costs and increasing project efficiency.

2. Protects Structural Integrity

Since beam clamps do not require the beam to be drilled or altered, they preserve the strength and integrity of the structure. This is especially important in industrial settings where maintaining the strength of support beams is critical for safety and longevity.

3. Adjustable and Versatile

Beam clamps come in adjustable sizes and designs to fit a variety of beam flanges and pitches. This makes them a versatile tool for projects where different beam sizes and shapes are encountered, offering flexibility to contractors and engineers.

4. Corrosion Resistance for Longevity

Many of our beam clamps feature corrosion-resistant finishes like hot-dip galvanizing or zinc plating, ensuring that they last even in harsh environments. This durability makes them suitable for both indoor and outdoor applications, including areas exposed to moisture, chemicals, or industrial pollutants.

5. Compliance with Safety Standards

Beam clamps are manufactured to meet rigorous safety standards, ensuring that they can handle the heavy loads required in industrial and commercial settings. Compliance with standards such as BS EN ISO 1461:2009 for galvanized finishes guarantees the highest level of quality and safety.

Choosing the Right Beam Clamp for Your Project

When selecting a beam clamp, it’s essential to consider the load capacity, flange width compatibility, and the environment where it will be used. For heavier loads or outdoor use, choose a clamp with a hot-dip galvanized finish for superior corrosion resistance. For smaller loads or indoor applications, a zinc-plated or self-colour clamp may suffice.

If you are working with pitched beams, ensure that you choose a clamp designed specifically for angled surfaces to guarantee a secure fixing.

Conclusion

Beam Clamps or Girder Clamps offer an efficient, secure, and flexible solution for suspending fixtures, threaded rods, electrical conduits, and more to beam flanges. By eliminating the need for welding or drilling, they preserve the integrity of the structural beams while providing reliable support for heavy loads. With options available for both flat and pitched beams, as well as various finishes to suit different environments, beam clamps are an essential tool in any construction or industrial installation.

Explore our range of beam clamps to find the perfect solution for your next project, whether it’s supporting pipework, securing HVAC systems, or installing electrical frameworks.

Showing all 11 results

-

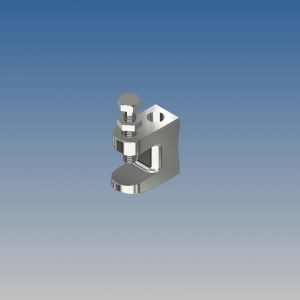

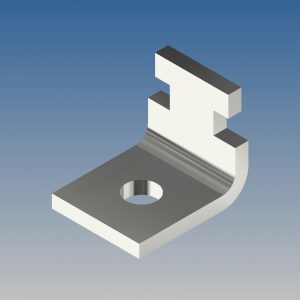

Drilled Beam Clamps

£1.00 Select options -

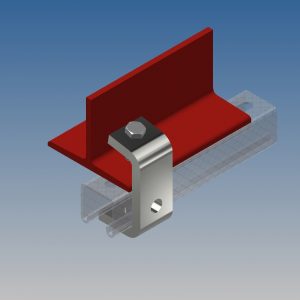

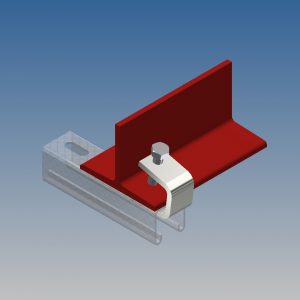

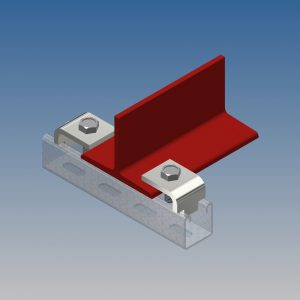

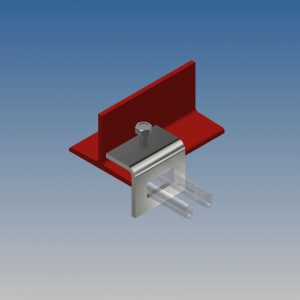

P1271 Tapped Channel Beam Clamps Large

£0.01 Add to quote -

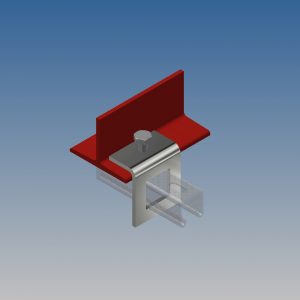

P1272 Tapped Channel Beam Clamps Mini

£0.01 Add to quote -

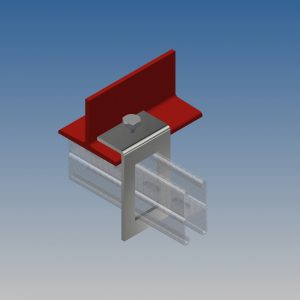

P1386 Channel Beam Clamps

£0.01 Add to quote -

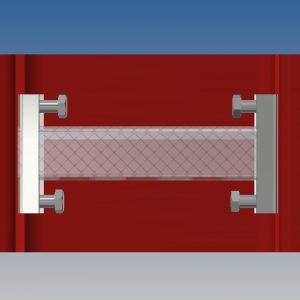

P1796 41×41 Window Bracket

£0.01 Add to quote -

P1796A 41×21 Window Bracket

£0.01 Add to quote -

P1796B 41×82 Window Bracket

£0.01 Add to quote -

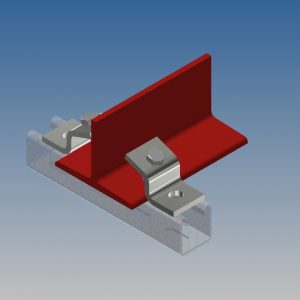

P1983 Tapped Z Beam Clamps

£0.01 Add to quote -

P2489 Heavy Duty Tapped Beam Clamps

£0.01 Add to quote -

P2785 Single Channel U Bolt Assembly

£0.01 Add to quote -

P3087 Internal Beam Clamps

£0.01 Add to quote

Showing all 11 results