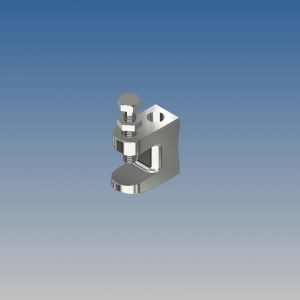

drilled clamp

Drilled Clamp: Secure and Efficient Structural Connections

Drilled beam clamps are essential devices in construction and industrial settings, designed to securely attach components to structural steel beams without compromising the integrity of the materials. They provide a reliable solution for support, lifting, and rigging applications, eliminating the need for drilling or welding, which can alter the structural properties of steel beams.

Key Features and Benefits

- Preservation of Structural Integrity: By clamping onto beams without drilling or welding, these clamps maintain the original strength and integrity of the structural steel, preventing potential weaknesses or damage.

- Versatility: Drilled beam clamps are suitable for a wide range of applications, including supporting pipework, cable trays, and HVAC systems. Their adjustable design allows for use with various beam sizes and configurations.

- Ease of Installation: These clamps can be quickly and securely attached to beams without the need for specialized tools or equipment, reducing installation time and labor costs.

- Adjustability: Unlike fixed connection methods, drilled beam clamps offer the flexibility to adjust and realign connections during installation, accommodating variations in beam dimensions or alignment.

Applications

Drilled beam clamps are utilized in various sectors for multiple purposes:

- Support Systems: Ideal for suspending electrical conduits, pipework, and HVAC ducts from structural beams.

- Lifting and Rigging: Serve as anchor points for hoisting equipment, providing secure attachment without altering the beam structure.

- Temporary Structures: Useful in assembling temporary frameworks or supports, as they can be easily installed and removed without damaging the existing structure.

Installation Considerations

- Beam Compatibility: Ensure the selected clamp is compatible with the beam’s size and load requirements.

- Load Capacity: Verify that the clamp’s rated load capacity meets or exceeds the demands of the application to maintain safety and performance.

- Regular Inspection: Conduct periodic inspections to check for signs of wear, corrosion, or loosening, especially in environments exposed to harsh conditions.

In summary, drilled beam clamps offer a secure, efficient, and non-invasive method for attaching components to structural steel beams. Their design preserves the integrity of the existing structure while providing flexibility and ease of installation, making them a valuable asset in various construction and industrial applications.

Showing the single result

Showing the single result