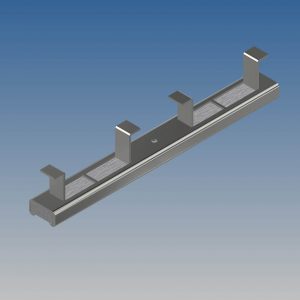

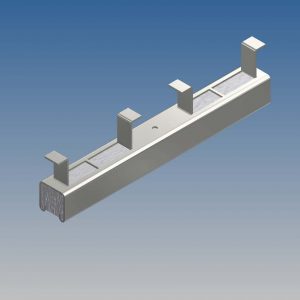

concrete insert

Concrete Insert: Pre-Set Support Systems for Flexible Attachments in Concrete Structures

Concrete inserts, or continuous slot concrete inserts or anchor channels, are pre-engineered support systems cast into concrete ceilings, walls, and floors. They provide a flexible attachment point along the channel, facilitating the secure installation of various building components.

Key Features of Concrete Inserts

- Pre-Set Support System: Designed to be embedded during the concrete pouring process, these inserts offer a ready-made support framework within the structure.

- Continuous Slot Design: The continuous slot allows for attachments at any point along the channel, providing flexibility in positioning and accommodating adjustments during installation.

- Material and Finish: Typically constructed from steel, concrete inserts are available in various finishes, including pre-galvanized and hot-dipped galvanized, to suit different environmental conditions.

Applications of Concrete Inserts

Concrete inserts are versatile and can be used in a variety of applications, including:

- Pipe and Conduit Support: Ideal for supporting pipes and conduits in mechanical and electrical installations.

- Cable Tray Support: Provide a robust support system for cable trays, ensuring organized and secure routing of cables.

- Equipment Mounting: Facilitate the attachment of heavy equipment to concrete structures, ensuring stability and safety.

Benefits of Using Concrete Inserts

- Flexibility: Allow for adjustments and repositioning of attachments without drilling or welding, preserving the integrity of the concrete structure.

- Time Efficiency: Simplify the installation process by providing predefined attachment points, reducing labor time and costs.

- Structural Integrity: Distribute loads evenly across the concrete structure, minimizing stress concentrations and potential damage.

Installation Considerations

- Proper Placement: Ensure accurate placement during the concrete pours to align with the intended attachment points.

- Secure Anchoring: Use appropriate anchors and fasteners compatible with the insert’s material and the load requirements.

- Corrosion Protection: Select inserts with suitable finishes to prevent corrosion, especially in environments exposed to moisture or chemicals.

For more detailed information on concrete inserts and their applications, you can refer to resources provided by manufacturers such as Unistrut.

Showing all 2 results

Showing all 2 results