Comprehensive Guide to Metal Clips: Types, Manufacturing, and Applications

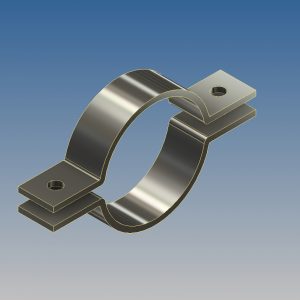

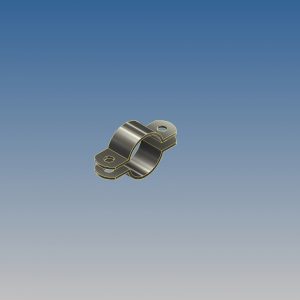

Metal clips are versatile and widely used fastening solutions across numerous industries. They come in various forms, including spring clips, clasps, and catches, each serving a distinct purpose in securing, holding, or fastening materials together. Typically manufactured through the metal stamping process, they are made from a broad range of metals, including carbon steel, stainless steel, aluminum, bronze, and brass. Their durability, strength, and adaptability make them essential components in automotive, aerospace, construction, and consumer applications.

Types of Metal Clips

They are available in various designs, each tailored for specific uses. Some of the most common types include:

1. Spring Clips

These utilize tension to grip or fasten objects securely. They are commonly found in:

- Automotive industry (securing wiring and hoses)

- Industrial machinery (holding components in place)

- Office supplies (binder clips and paper fasteners)

2. Clasps

Clasps are small fastening devices that allow objects to be quickly secured and released. They are widely used in:

- Jewelry (necklace and bracelet clasps)

- Handbags and accessories (securing straps and compartments)

- Outdoor gear (buckles and fasteners on backpacks and harnesses)

3. Catches

Catches are mechanical latching devices that hold components securely together. These are typically seen in:

- Cabinet and furniture hardware (magnetic and push-to-open catches)

- Electronics and enclosures (battery compartment latches)

- Automotive applications (hood latches and glove compartment locks)

Manufacturing Process: Metal Stamping

Metal clips are primarily produced using the metal stamping process, a high-precision method that involves:

- Material Selection: Choosing the right metal based on durability, corrosion resistance, and strength.

- Die Cutting and Forming: Using specialized dies to shape the metal into the desired clip design.

- Heat Treatment: Enhancing strength and elasticity through controlled heating and cooling processes.

- Surface Finishing: Applying coatings such as zinc plating, chrome finish, or powder coating for additional protection and aesthetics.

Metal stamping ensures mass production of high-quality, cost-effective metal clips with uniform shapes and specifications.

Materials Used in Metal Clips

They can be made from various materials, each selected based on its application requirements:

- Carbon Steel – High-strength material used in industrial applications.

- Stainless Steel – Corrosion-resistant and durable, ideal for outdoor and marine environments.

- Aluminum – Lightweight and resistant to rust, commonly used in aerospace and automotive applications.

- Bronze & Brass – Excellent electrical conductivity, used in electrical and decorative applications.

Applications

1. Automotive Industry

- Securing wire harnesses and tubing

- Fastening panels and trim components

- Holding hoses and pipes in place

2. Aerospace and Defense

- Lightweight fastening solutions for aircraft interiors

- High-strength clips for secure attachment in extreme conditions

- Corrosion-resistant materials for long-term durability

3. Construction and Engineering

- Structural fasteners for beams and framework

- Secure attachment of cables and conduits

- HVAC and plumbing support systems

4. Consumer Goods

- Binder clips and stationery products

- Clothing fasteners (e.g., belt clasps, suspender clips)

- Home organization solutions (e.g., chip bag clips, tool hangers)

Choosing the Right Metal Clip

Consider the following factors:

- Load Capacity – Ensure the clip can withstand the required weight or force.

- Environmental Conditions – Opt for corrosion-resistant materials in humid or outdoor settings.

- Size and Shape – Choose a clip that fits the application dimensions accurately.

- Ease of Installation – Look for versions that allow quick and secure attachment without specialized tools.

Conclusion

They are indispensable components in various industries, offering secure, durable, and versatile fastening solutions. By understanding the different types available, their manufacturing processes, and their material choices, businesses, and consumers can select the best clips for their needs. Whether in automotive, construction, aerospace, or consumer products, they continue to provide reliable and efficient fastening solutions.

Showing all 2 results

Showing all 2 results