Comprehensive Guide to Metal Clip: Types, Manufacturing Processes, and Materials

A Metal clip is an indispensable component across various industries, serving functions from securing components in machinery to organizing documents in offices. Understanding the diverse types of metal clips, their manufacturing processes, and the materials used in their production is crucial for selecting the appropriate clip for specific applications.

Types of Metal Clips

Metal clips come in various forms, each designed to meet specific functional requirements:

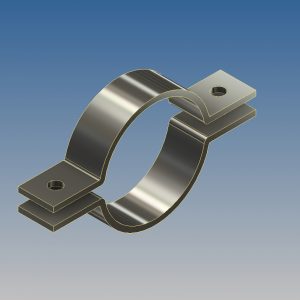

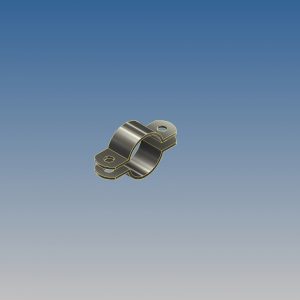

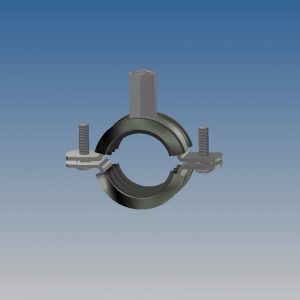

- Spring Clips: Utilize the inherent elasticity of metal to exert a holding force. Common types include R-clips, linchpins, and hose clamps.

- Clasps: Often used in jewelry and accessories, clasps provide a secure yet releasable connection between two ends.

- Catches: Employed in closures for boxes, cases, and doors, catches ensure secure fastening and easy access when needed.

- U-Base Metal Clips: Designed for fastening interior trim and panels with hidden fasteners, offering an ergonomic and efficient solution.

- Edge Clips: Attach to the edge of a panel or component, providing a secure hold without the need for drilling or additional hardware.

Manufacturing Process: Metal Stamping

The majority of metal clips are produced through the metal stamping process, a versatile and efficient manufacturing technique that involves:

- Design and Tooling: Creating precise dies that define the clip’s shape and features.

- Material Selection: Choosing appropriate metals based on the clip’s intended application and required properties.

- Stamping: Feeding metal sheets or coils into stamping presses equipped with the designed dies to form the clips.

- Finishing: Applying surface treatments such as plating or coating to enhance durability and appearance.

Metal stamping allows for high-volume production of complex clip designs with consistent quality and precision.

Materials Used in Metal Clips

Selecting the right material is crucial for the performance and longevity of metal clips. Common materials include:

- Carbon Steel: Offers high strength and durability, suitable for heavy-duty applications.

- Stainless Steel: Provides excellent corrosion resistance, ideal for environments exposed to moisture or chemicals.

- Aluminum: Lightweight and corrosion-resistant, used where weight reduction is essential.

- Copper and Brass: Exhibit good electrical conductivity, making them suitable for electrical applications.

- Phosphor Bronze: Known for its elasticity and fatigue resistance, often used in spring clips.

The choice of material depends on factors such as mechanical requirements, environmental conditions, and cost considerations.

Applications of Metal Clips

Metal clips are utilized across a wide range of industries and applications:

- Automotive: Securing interior panels, trim, and components.

- Electronics: Holding circuit boards, cables, and connectors in place.

- Construction: Fastening building materials and structural elements.

- Aerospace: Providing lightweight fastening solutions for aircraft components.

- Consumer Goods: Used in products like clothing, accessories, and stationery for fastening purposes.

Understanding the specific requirements of each application ensures the selection of the most appropriate clip type and material.

Conclusion

Metal clips are versatile components essential in numerous applications. By comprehending the various types of clips, the metal stamping manufacturing process, and the materials used, one can make informed decisions to meet specific functional and environmental requirements. This knowledge ensures the selection of metal clips that offer optimal performance, durability, and efficiency in their intended applications.

Showing all 3 results

Showing all 3 results