Channel Support Systems Brackets: Essential Components for Building Services

Introduction to Channel Support Systems Brackets

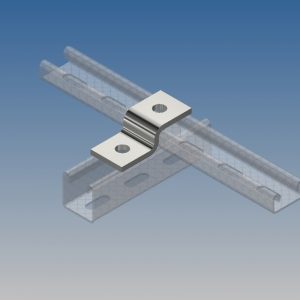

Channel support systems brackets are critical components in modern construction and industrial infrastructure, providing robust support for various building services. These brackets are an integral part of channel support systems, ensuring the secure installation of electrical, mechanical, and plumbing systems.

From basic brackets for small cable runs and pipe supports to complex frameworks for large-scale installations—such as data cabling, plant room pipework, and full-building HVAC systems—these brackets are essential for maintaining structural integrity and operational efficiency.

What Are Channel Support System Brackets?

Channel support system brackets are metal fittings designed to connect, reinforce, and support strut channels used in construction and engineering projects. These brackets help create modular, load-bearing structures that distribute weight efficiently while allowing for future modifications and expansions.

Key Functions of Channel Support System Brackets

Channel support system brackets play a crucial role in various industrial and commercial applications:

- Supporting Electrical Systems – Organizes and holds electrical conduits, cable trays, and wiring harnesses in place.

- Carrying Pipework – Provides sturdy mounting points for water, gas, and HVAC piping systems.

- Structural Reinforcement – Strengthens framework assemblies for industrial, warehouse, and commercial applications.

- Load Distribution – Helps distribute the weight of attached systems evenly, reducing strain on individual components.

- Flexible Configuration – Allows for easy reconfiguration and expansion without extensive modifications.

Applications of Channel Support System Brackets

1. Electrical & Cable Management Systems

- Organizes power and data cabling for commercial and industrial buildings.

- Supports cable trays, electrical conduits, and wiring harnesses.

2. Plumbing & Pipework Installations

- Provides stable support for water supply and drainage pipes.

- Helps prevent pipe movement and sagging, ensuring long-term reliability.

3. HVAC Installations

- Supports ductwork, fans, and air-handling units.

- Reduces vibration and ensures a stable, secure installation.

4. Industrial & Commercial Structural Frameworks

- Used in constructing shelving units, conveyor systems, and equipment racks.

- Adaptable for use in warehouses, factories, and production facilities.

5. Renewable Energy Systems

- Provides mounting solutions for solar panels and other renewable energy installations.

- Designed to withstand environmental elements for long-term durability.

Types of Channel Support System Brackets

There are multiple types of channel support system brackets designed to meet various structural requirements:

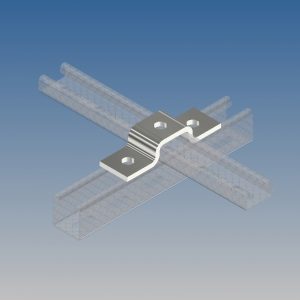

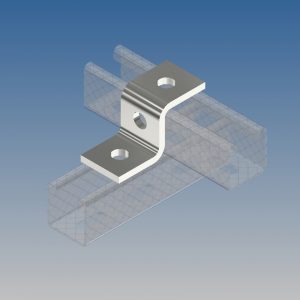

- Angle Brackets – Used to create 90-degree connections, commonly found in framing applications.

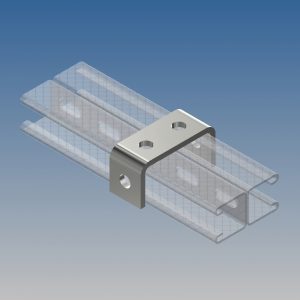

- Flat Brackets – Connect two strut channels in a straight-line extension, adding stability and support.

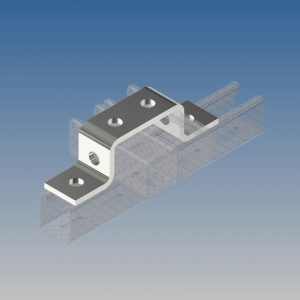

- U-Shaped Brackets – Wrap around strut channels, offering enhanced reinforcement for heavy loads.

- Z-Brackets – Used for elevated connections, enabling installation flexibility.

- Gusseted Brackets – Reinforced for extra strength, making them ideal for high-load environments.

Advantages of Using Channel Support System Brackets

1. High Versatility

Available in various shapes and configurations, these brackets can be used in diverse construction applications.

2. Quick & Easy Installation

Designed for fast assembly with minimal tools, reducing labor costs and project timelines.

3. Exceptional Durability

Made from galvanized steel, stainless steel, or powder-coated materials, ensuring corrosion resistance and long-term strength.

4. Cost-Effective

Eliminates the need for welding or complex metal fabrication, offering a modular and budget-friendly alternative.

5. Expandable & Adjustable

Easily modified for future expansions or changes in the building layout.

Choosing the Right Channel Support System Brackets

When selecting brackets for your project, consider:

- Load Capacity – Ensure the bracket can support the required weight without compromising safety.

- Material & Coating – Choose between galvanized, stainless steel, or powder-coated finishes based on environmental exposure.

- Installation Requirements – Select brackets that match the configuration and layout of your structure.

- Corrosion Resistance – For outdoor or high-humidity environments, opt for weather-resistant materials.

Conclusion

Channel support system brackets are fundamental components in the construction of secure, adaptable, and cost-effective support systems. Whether for electrical, plumbing, HVAC, industrial, or renewable energy applications, these brackets ensure reliable connections and structural stability.

By incorporating the right channel support system brackets, businesses and contractors can build durable, high-performance frameworks suited for a wide range of applications.

Showing all 10 results

-

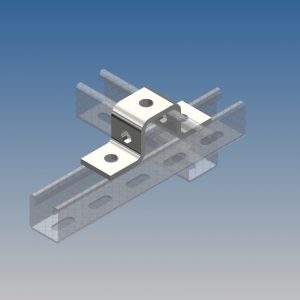

CB55 P4047 Top Hat Bracket

£0.01 Add to quote -

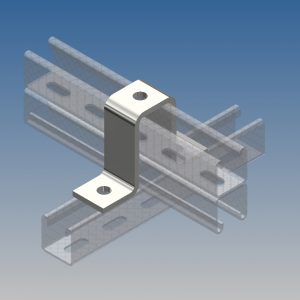

P1043 Top Hat Bracket

£0.01 Add to quote -

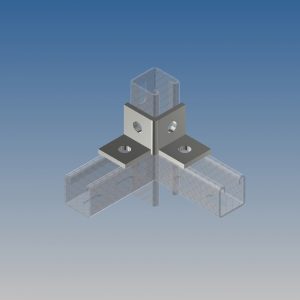

P1044 C Bracket

£0.01 Add to quote -

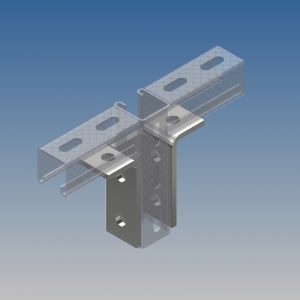

P1045 Z Bracket

£0.01 Add to quote -

P1047 Top Hat Bracket

£0.01 Add to quote -

P1354 Hinge Bracket

£0.01 Add to quote -

P1737 Top Hat Bracket

£0.01 Add to quote -

P2223 Wing Bracket

£0.01 Add to quote -

P2346 Tower Bracket

£0.01 Add to quote -

P4045 Z Bracket

£0.01 Add to quote

Showing all 10 results