channel support brackets

Strut Channel Support Brackets: Essential Components for Versatile Structural Frameworks

Strut channel support brackets play a crucial role in construction and industrial applications, providing a strong and adaptable method for connecting strut channel sections. These brackets allow for the assembly of various configurations, enabling the creation of durable and versatile structures. When used alongside strut channels, clamps, fasteners, and other essential fittings, they form the backbone of support systems used in mechanical, electrical, and industrial installations.

What Are Strut Channel Support Brackets?

Strut channel support brackets are specialized metal components designed to join, reinforce, and stabilize strut channels in different layouts. They are typically manufactured from galvanized steel, stainless steel, or aluminum, ensuring long-lasting durability and resistance to corrosion, making them suitable for both indoor and outdoor applications.

Key Functions of Strut Channel Support Brackets

These brackets serve several essential functions:

- Connecting Strut Channels – They securely join strut sections at different angles, enabling the construction of support structures, frames, and racks.

- Providing Stability – By reinforcing connections, they prevent movement and ensure a rigid framework.

- Weight Distribution – These brackets help evenly distribute loads across the structure, reducing strain on individual components.

- Modular Assembly – They enable easy modifications and adjustments, making them ideal for dynamic installations.

Common Applications of Strut Channel Support Brackets

Strut channel systems, along with their brackets, are widely used in various industries due to their adaptability and ease of installation. Some of the most common applications include:

1. Electrical & Cable Management Systems

- Support for electrical conduits, cable trays, and enclosures.

- Provides a neat, organized framework for power and data cabling.

2. Plumbing & Piping Systems

- Secure mounting of pipes in commercial and industrial buildings.

- Helps maintain alignment and prevents sagging.

3. HVAC Installations

- Support for ductwork, fans, and air-handling units.

- Reduces vibration and ensures a stable mounting system.

4. Industrial & Manufacturing Facilities

- Construction of machine frames, storage racks, and conveyor supports.

- Customizable for various load-bearing requirements.

5. Solar Panel Mounting Systems

- Provides a strong base for solar arrays in renewable energy installations.

- Resistant to environmental factors such as wind and corrosion.

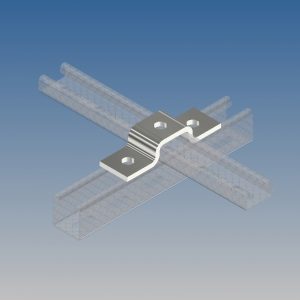

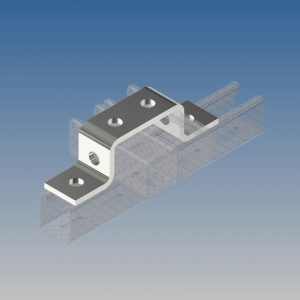

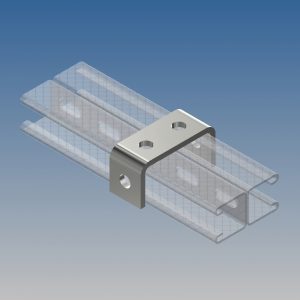

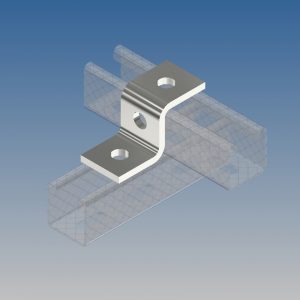

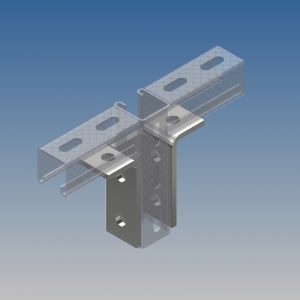

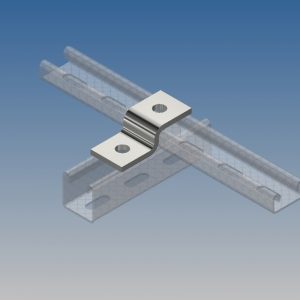

Types of Strut Channel Support Brackets

To accommodate different structural needs, strut channel brackets come in various designs, including:

- Angle Brackets – Used to create 90-degree connections for strong corner joints.

- Flat Brackets – Help join two strut channels in a straight-line extension.

- U-Brackets – Wrap around the channel, adding extra reinforcement for heavy loads.

- Z-Brackets – Allow for mounting at staggered heights or unique structural configurations.

- Gusseted Brackets – Reinforced for extra strength in high-load applications.

Benefits of Using Strut Channel Support Brackets

1. Versatility

With a wide range of bracket types, they can be used to construct complex support structures tailored to specific project needs.

2. Ease of Installation

These brackets are designed for quick assembly, often requiring only basic tools, reducing labor costs and installation time.

3. Durability & Strength

Manufactured from high-quality materials, they withstand heavy loads, vibrations, and harsh environments.

4. Cost-Effective

Compared to traditional welded frames, strut channel systems with brackets offer a flexible, reusable, and budget-friendly solution.

5. Adjustable & Expandable

The modular nature of these brackets allows for easy modifications and expansions without major structural overhauls.

Choosing the Right Strut Channel Support Bracket for Your Project

When selecting the appropriate bracket for your application, consider factors such as:

- Load Capacity – Ensure the bracket can support the weight requirements of your installation.

- Material & Coating – Choose between galvanized, stainless steel, or powder-coated finishes for optimal performance.

- Environmental Conditions – Consider corrosion resistance if used in outdoor or humid environments.

- Mounting Requirements – Select the right bracket type based on the configuration and angle of your structure.

Conclusion

Strut channel support brackets are essential for building strong, adaptable, and cost-effective structural frameworks across various industries. Whether used in electrical, plumbing, HVAC, or industrial applications, these brackets ensure secure connections, weight distribution, and structural integrity. Their modularity, durability, and ease of installation make them a preferred choice for engineers, contractors, and installers looking for reliable support solutions.

By incorporating the right strut channel brackets into your project, you can create a strong, versatile, and efficient support system tailored to your specific needs.

Showing all 11 results

-

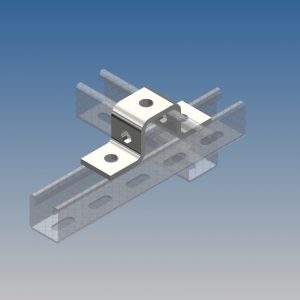

CB55 P4047 Top Hat Bracket

£0.01 Add to quote -

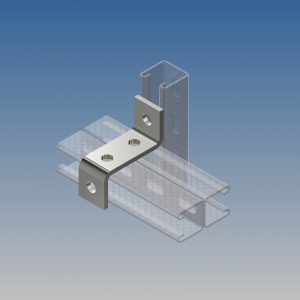

P1043 Top Hat Bracket

£0.01 Add to quote -

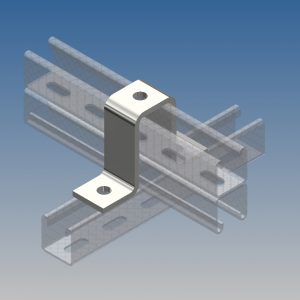

P1044 C Bracket

£0.01 Add to quote -

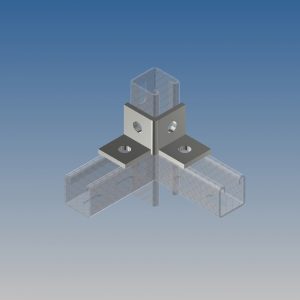

P1045 Z Bracket

£0.01 Add to quote -

P1047 Top Hat Bracket

£0.01 Add to quote -

P1354 Hinge Bracket

£0.01 Add to quote -

P1453 Z Bracket

£0.01 Add to quote -

P1737 Top Hat Bracket

£0.01 Add to quote -

P2223 Wing Bracket

£0.01 Add to quote -

P2346 Tower Bracket

£0.01 Add to quote -

P4045 Z Bracket

£0.01 Add to quote

Showing all 11 results