Channel bracketry plays a pivotal role in various industries, providing robust solutions for supporting, bracing, mounting, and connecting lightweight loads. These components are integral to the construction and electrical sectors, facilitating the installation of piping, wiring, and mechanical systems such as plumbing, ventilation, and air conditioning.

What Is Channel Bracketry?

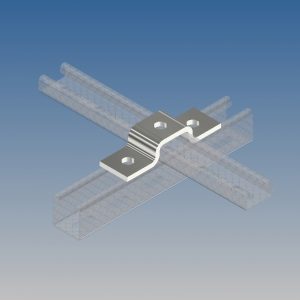

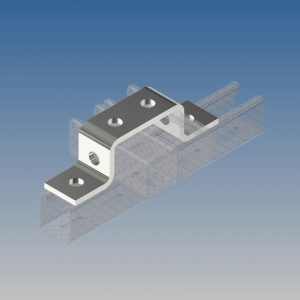

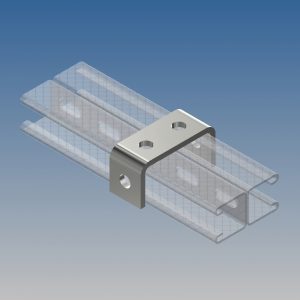

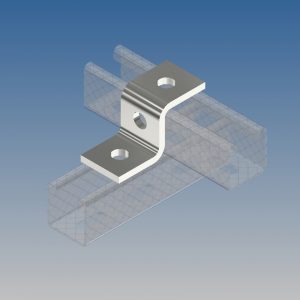

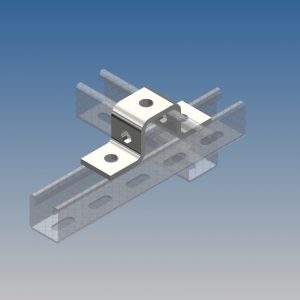

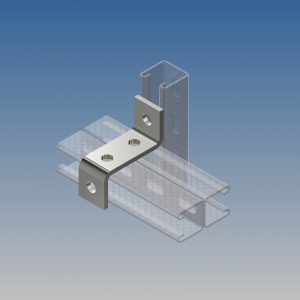

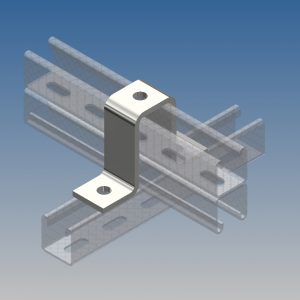

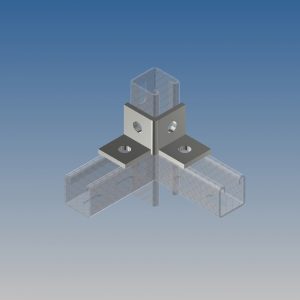

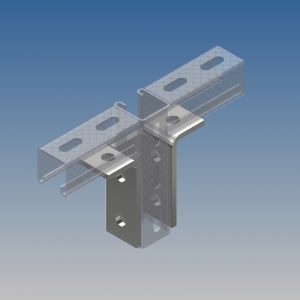

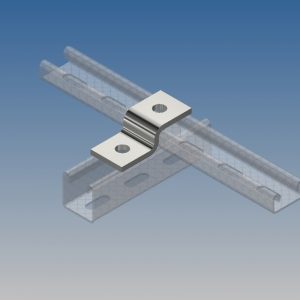

Channel bracketry comprises a range of hardware components designed to work in conjunction with strut channels. These brackets are engineered to support and secure various systems, ensuring stability and safety in installations. They are commonly used to mount panels, support structural frameworks, and secure conduits or pipes.

Key Features and Benefits

- Versatility: Channel brackets are available in various designs, including corner brackets, surface brackets, and offset-surface brackets, allowing for flexible configurations to meet diverse installation requirements.

-

Durability: Manufactured from high-quality materials such as steel and aluminum, these brackets are built to withstand environmental stresses, ensuring long-term performance.

- Ease of Installation: Designed for quick and easy installation, channel brackets eliminate the need for welding or drilling, streamlining the assembly process.

-

Load Distribution: Properly selected and installed channel brackets effectively distribute loads, enhancing the structural integrity of the entire system.

Applications of Channel Bracketry

Channel bracketry is utilized in various applications, including:

- Piping and Conduit Support: Providing secure mounting solutions for pipes and conduits in plumbing and electrical installations.

- Structural Framing: Serving as essential components in building frameworks, offering support and stability.

- Mechanical Systems Installation: Facilitating the secure mounting of mechanical systems such as HVAC units, ensuring proper alignment and support.

Selecting the Right Channel Bracket

When choosing a channel bracket, consider the following factors:

- Material Compatibility: Ensure the bracket material is suitable for the environmental conditions and compatible with the strut channel.

- Load Requirements: Assess the weight and load requirements of the system to ensure the bracket can provide adequate support.

- Installation Environment: Consider factors such as exposure to chemicals, temperature variations, and humidity to select a bracket with the appropriate finish and material properties.

Conclusion

Channel bracketry is a fundamental component in creating secure and reliable mounting solutions across various industries. By understanding their features, benefits, and applications, you can make informed decisions to enhance the safety and efficiency of your installations.