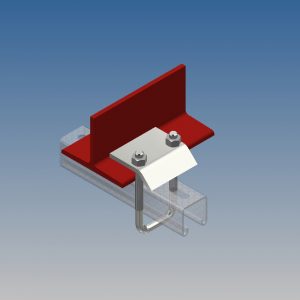

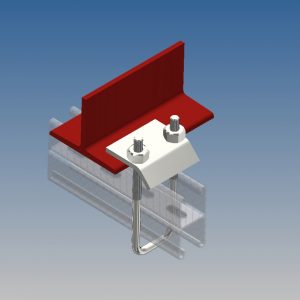

Beam Clamp and U Bolt: Secure Channel Installation for I-Beams

Overview of Beam Clamp and U Bolt Systems

The Beam Clamp and U Bolt system is an essential solution for securely fastening strut channels onto structural I-beams in various building and industrial installations. The combination of the beam clamp and U-bolt offers a sturdy, flexible, and reliable method for attaching strut channels without needing welding or drilling, making it a popular choice for projects requiring robust support in ceilings or roof structures.

This system is designed to provide maximum load support, making it ideal for suspending electrical conduits, HVAC systems, pipework, and other fixtures that require reliable overhead mounting.

Key Features of Beam Clamp and U Bolt

1. Efficient Channel Installation

Beam clamps, paired with U-bolts, allow for quick and secure attachment of strut channels to steel I-beams. This method ensures a solid connection, enabling the strut channel to support heavy loads or act as a mounting base for various types of equipment.

2. Secure Fastening with M10 Nuts

The system uses M10 nuts to fasten the U-bolt securely around the strut channel and beam. The nuts are tightened, pressing the strut channel down firmly onto the I-beam, ensuring the structure remains rigid even under heavy loads.

3. No Need for Welding or Drilling

This clamping system eliminates the need for permanent modifications like welding or drilling. Instead, the beam clamp and U-bolt secure the strut channel with minimal impact on the integrity of the I-beam. This makes the installation faster, easier, and more cost-effective while maintaining the strength of the structural beam.

4. Heavy-Duty Support for Industrial Use

Beam clamps and U bolts are engineered for heavy-duty applications, ensuring they can support high loads. They are commonly used in industrial and commercial environments where the suspension of heavy fixtures such as pipework, HVAC systems, or electrical installations is required.

Technical Specifications of Beam Clamp and U Bolt

- Materials: Made from durable steel, often hot-dip galvanized for corrosion resistance

- Bolt Size: Compatible with M10 nuts for a secure fit

- Finish: Available in zinc-plated or hot-dip galvanized finishes, offering excellent protection against rust and corrosion, making them suitable for indoor and outdoor use

- Beam Compatibility: Designed to fit standard I-beams of various sizes and shapes

- Channel Compatibility: Suitable for securing standard strut channels in sizes such as 41mm x 21mm or 41mm x 41mm

Applications of Beam Clamp and U Bolt Systems

1. Strut Channel Support

The most common use of the beam clamp and U-bolt system is to secure strut channels to I-beams in roof or ceiling installations. Once in place, the strut channel serves as a support system for other components, such as electrical conduits, piping, or cable trays.

2. Suspension of Electrical and Mechanical Systems

Beam clamp and U-bolt systems are widely used to suspend electrical or mechanical components from the ceiling. These include lighting fixtures, air ducts, and mechanical piping, making them essential for industries like construction, commercial building, and manufacturing.

3. HVAC and Plumbing Installations

In HVAC and plumbing installations, beam clamps and U-bolts provide secure overhead suspension of ducts, piping, and equipment. This method offers flexibility and ease of maintenance, ensuring that components are securely mounted but can also be adjusted or removed as needed.

4. Overhead Cable Management

Beam clamps, combined with U-bolts, are used to mount strut channels, which act as cable management trays for holding electrical wiring in industrial settings. This system ensures the cables are organized and securely supported overhead, reducing clutter and preventing potential damage.

Installation Process for Beam Clamp and U-Bolt Systems

Step 1: Prepare the Components

Begin by selecting the appropriate size U-bolt and beam clamp for the I-beam and strut channel being installed. Ensure that the U-bolt is the correct size to encircle the strut channel securely and that the M10 nuts are compatible.

Step 2: Position the Beam Clamp

Position the beam clamp onto the flange of the I-beam in the desired location. This should be the area where the strut channel will be mounted.

Step 3: Attach the U-Bolt

Slide the U-bolt around the strut channel and through the holes in the beam clamp. This secures the channel against the I-beam while allowing the U-bolt to hold it firmly in place.

Step 4: Tighten the M10 Nuts

Once the U-bolt is in place, use two M10 nuts to fasten the U-bolt around the strut channel. Tighten the nuts securely until the channel is pressed down onto the I-beam. Ensure that the system is tight enough to prevent movement but not so tight that it causes deformation of the components.

Step 5: Final Adjustments

Make any final adjustments to the strut channel’s positioning before completing the installation. Ensure that the channel is level and properly aligned with the other components of the installation.

Advantages of Using Beam Clamp and U-Bolt Systems

1. Quick and Easy Installation

Using a beam clamp and U-bolt system allows for quick and easy installation of strut channels onto I-beams. This method eliminates the need for complex equipment or lengthy installation processes, reducing labor costs and project timelines.

2. Non-Permanent Fixing

Since the system does not require welding or drilling, it offers a non-permanent fixing solution that preserves the structural integrity of the beam. This makes it ideal for temporary installations or applications where components may need to be relocated or adjusted over time.

3. Cost-Effective Solution

By eliminating the need for specialized tools or labor-intensive processes like welding, the beam clamp and U-bolt system offers a cost-effective solution for installing strut channels and other components in industrial environments.

4. Corrosion Resistance

With finishes such as hot-dip galvanizing or zinc plating, the beam clamp and U-bolt system is highly resistant to rust and corrosion. This makes it suitable for both indoor and outdoor use, even in harsh environments like factories, warehouses, and outdoor facilities.

5. Flexibility and Versatility

The beam clamp and U-bolt system can be used for various applications and on a range of beam sizes. It’s an adaptable solution that can support everything from lightweight electrical conduits to heavy-duty mechanical equipment, offering great versatility for different industries.

Conclusion

The Beam Clamp and U-Bolt system provides a robust, efficient, and flexible solution for securing strut channels onto structural I-beams. By offering a secure connection without the need for welding or drilling, this system ensures faster installation, protects the integrity of the beam, and is highly versatile for a wide range of applications, from HVAC systems to overhead electrical wiring.

With its heavy-duty load capacity, corrosion-resistant finishes, and easy installation process, the beam clamp and U-bolt combination is an ideal choice for contractors and engineers looking for a reliable and cost-effective way to support overhead fixtures in both commercial and industrial settings.

Showing all 2 results

Showing all 2 results