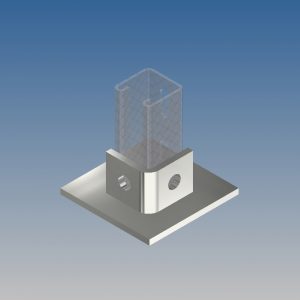

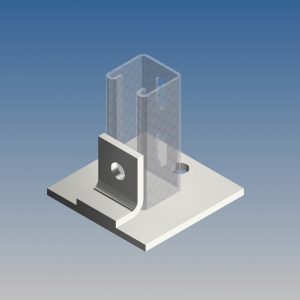

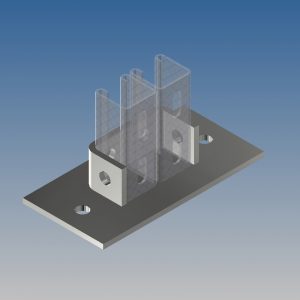

Base Plate: Reliable Structural Support for Construction Projects

What is a Base Plate?

A Base Plate is a crucial structural component used in a wide range of construction and engineering projects. Typically made from durable materials such as steel, these plates provide a stable foundation for columns, beams, and other load-bearing structures. By evenly distributing the weight and forces from above, base plates ensure that the underlying surface, whether concrete or another material, is not damaged or stressed beyond its capacity.

Available in Various Sizes and Materials

Our Base Plates are available in various dimensions and thicknesses to meet the needs of different structural requirements. Commonly used materials include hot-dipped galvanized steel and mild steel, with the choice of finishes ranging from galvanized to self-colour for increased corrosion resistance, ensuring longevity in both indoor and outdoor environments.

Key Features of Base Plates

1. Structural Integrity and Load Distribution

One of the primary purposes of a Base Plate is to evenly distribute the weight and pressure from the structure above onto a wider surface area. This helps prevent concentrated loads, reducing the risk of cracks or damage to the foundation. They are especially vital in supporting beams, columns, or Unistrut channel systems, which carry significant weight in construction and industrial settings.

2. Corrosion Resistance and Durability

Many of our Base Plates come with a hot-dip galvanized finish according to BS EN ISO 1461:2009, providing excellent resistance to corrosion. This makes them suitable for both indoor and outdoor use, even in harsh environments such as marine, industrial, or humid conditions.

3. Versatile Applications

Base Plates are not only used in building construction but also in mechanical installations, pipe support systems, and electrical frameworks. They provide stability for heavy-duty machinery, equipment stands, and electrical conduits. Whether used in structural steel frameworks or in supporting lighter fixtures, base plates ensure solid and dependable foundations.

Technical Specifications

- Material Options: Steel, Galvanized Steel, Stainless Steel

- Finish: Hot-Dip Galvanized, Zinc-Plated, or Self-Colour

- Available Sizes: Customizable sizes to suit specific construction needs

- Hole Configuration: Multiple hole patterns available for easy bolting or anchoring

- Weight: Depending on dimensions and material, from lightweight options to heavy-duty base plates

Common Dimensions for Base Plates

Some of the standard sizes we offer include:

- 100mm x 100mm

- 150mm x 150mm

- 200mm x 200mm

- Thickness options range from 5mm to 10mm or more, depending on load requirements.

Custom sizes can also be fabricated to meet unique project needs, ensuring that each plate provides the necessary support for any specific application.

Applications of Base Plates in Construction

1. Structural Steel Support

In the construction of large structures like buildings, bridges, and industrial facilities, Base Plates serve as the foundation for steel columns. They are designed to evenly distribute the load across the concrete foundation, ensuring structural integrity and preventing cracking or sinking of the surface. When bolted down, these plates form a secure anchor point for beams or pillars, keeping the structure stable.

2. Pipe and Cable Management Systems

Base plates are frequently used in conjunction with Unistrut channel systems and pipe supports, providing a solid foundation to secure pipe clamps, brackets, and electrical conduits. By using base plates in pipe management systems, installations can handle heavier loads while maintaining proper alignment and stability.

3. Machinery and Equipment Foundations

For mechanical installations or industrial equipment, Base Plates offer an ideal solution for anchoring heavy machines to the ground. By providing a stable platform for machinery, base plates help reduce vibrations and ensure that equipment remains fixed and functional, especially in high-load scenarios.

4. Outdoor and Harsh Environment Applications

When used outdoors or in corrosive environments, galvanized base plates provide extra protection against the elements. These plates are often employed in outdoor structures such as towers, fences, and signposts, where the risk of rust or corrosion is high. The hot-dip galvanizing process ensures a thick, long-lasting coating that protects the plate from oxidation and environmental damage.

Benefits of Using a Base Plate

1. Enhanced Load Distribution

By spreading out the load from above, Base Plates help prevent concentrated pressure points that can lead to structural failure or damage. This is particularly important in areas with soft ground or where heavy loads are placed on small surface areas.

2. Easy Installation and Customization

Base plates come with pre-drilled holes, making them easy to anchor using bolts, screws, or welds. Additionally, they can be customized to meet the specific needs of any project, with multiple sizes, shapes, and hole configurations available to suit your structural design.

3. Corrosion Resistance for Long-Term Durability

Base plates made from galvanized steel or stainless steel are highly resistant to corrosion, ensuring longevity in outdoor environments or in settings where moisture or chemicals are present. This guarantees a longer lifespan for the support structure and minimizes the need for maintenance or replacement.

4. Versatility Across Different Industries

Base Plates are widely used across multiple industries, from construction and infrastructure projects to mechanical installations and pipework support systems. Their adaptability and load-bearing capacity make them an essential component in both large-scale construction and smaller, more precise engineering projects.

Compliance and Quality Standards

All our Base Plates are manufactured to meet industry standards, including BS EN ISO 1461:2009 for galvanized finishes. This ensures that every plate we supply is reliable, durable, and capable of withstanding harsh conditions, making it ideal for both structural and industrial applications.

Conclusion

Whether you’re working on a construction project, setting up a heavy-duty mechanical system, or need support for pipework or electrical conduits, Base Plates are a must-have for ensuring structural stability and load distribution. With customizable sizes, durable finishes like hot-dip galvanization, and compliance with industry standards, our base plates offer reliable performance across a wide range of applications. Invest in the best foundation for your project with our high-quality Base Plates.

Showing all 3 results

Showing all 3 results