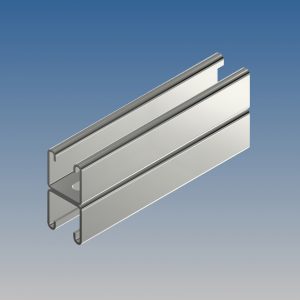

Back to Back Slotted Channel: Versatile and Durable for Heavy-Duty Installations

What is Back to Back Slotted Channel?

The Back to Back Slotted Channel is an essential component used in various industrial, construction, and mechanical applications. This design consists of two slotted channels joined back-to-back, providing enhanced structural support for projects that require higher load-bearing capabilities. The slotted channel design allows for easier mounting and adjustments, making it ideal for flexible installations in settings like pipework, electrical, and HVAC systems.

Key Features of Back to Back Slotted Channel

Enhanced Structural Strength

The Back to Back Slotted Channel is known for its superior strength. By connecting two slotted channels, this system offers increased stability, which is critical for heavy-duty applications such as:

- Pipe Support Systems: Ideal for securing large-diameter pipes used in industrial plumbing and HVAC systems.

- Electrical and Cable Management: Organizes and secures electrical conduits, cable trays, and wires.

- Framing and Mounting: Offers flexible support for construction frameworks, mounting brackets, and equipment racks.

Slotted Design for Versatility

The slotted channel design includes pre-punched holes, allowing for fast, adjustable installation. This feature offers enhanced flexibility in mounting, as the slots can accommodate various fixings such as bolts, nuts, and clamps. The slotted design is especially useful for applications where components need to be adjusted or repositioned after installation.

Corrosion-Resistant Hot-Dip Galvanised Finish

Our Back to Back Slotted Channels are coated with a Hot-Dip Galvanised finish, offering superior resistance to rust and corrosion. This finish complies with BS EN ISO 1461:2009 standards, making the channels suitable for both indoor and outdoor use in harsh environments. Whether used in industrial settings, outdoor construction, or exposed to weather elements, this galvanised finish ensures long-lasting performance.

Applications of Back to Back Slotted Channel

Pipe Support Systems

The Back to Back Slotted Channel provides excellent stability for pipe support systems. Its slotted design allows for the flexible mounting of brackets, clamps, and other supports, making it ideal for industrial plumbing and HVAC installations. The back-to-back configuration offers extra load-bearing capacity, ensuring that pipes remain secure and in place under heavy loads.

Cable Management and Electrical Installations

In electrical systems, the Back to Back Slotted Channel is a popular choice for securing cable trays, conduits, and wiring. The slotted design makes it easy to adjust the placement of cables and components, providing a clean and organized installation. This makes it highly suitable for commercial and industrial electrical projects where cable management is critical.

HVAC Systems and Ductwork

For HVAC systems, this channel configuration is often used to mount and support ductwork, ventilation systems, and air conditioning units. The back-to-back design ensures the required strength and stability for supporting large, heavy HVAC equipment while the slotted design allows for flexible positioning of components during installation.

Custom Framing and Mounting Solutions

The Back to Back Slotted Channel is frequently used in custom framing solutions where flexibility is key. Whether it’s constructing shelving units, equipment racks, or structural frames, this channel allows for easy adjustments during assembly. The slotted design simplifies mounting, making it adaptable for various project requirements.

Benefits of Back to Back Slotted Channel

Superior Load Capacity

By combining two slotted channels in a back-to-back configuration, this product offers greater load-bearing capacity than standard single channels. It’s perfect for applications that demand higher strength and stability, including industrial frameworks, pipe support, and heavy-duty shelving.

Easy and Adjustable Installation

The slotted design makes installation fast and straightforward. The pre-punched holes provide flexibility for mounting fixings such as bolts, nuts, clamps, and other fasteners. This makes the channel highly adaptable, allowing components to be moved or adjusted after initial installation.

High Resistance to Corrosion

The Hot-Dip Galvanised finish ensures protection from rust and corrosion, even in demanding environments. This finish extends the life of the Back to Back Slotted Channel, making it a reliable option for long-term installations both indoors and outdoors. It complies with BS EN ISO 1461:2009, a standard for galvanisation quality, ensuring a durable and dependable product.

Custom Sizes and Lengths Available

To accommodate a variety of project needs, our Back to Back Slotted Channels are available in a range of lengths, widths, and thicknesses. Custom sizes can also be provided to meet the specific requirements of your application, ensuring a perfect fit every time.

Technical Specifications

- Material: High-quality steel for enhanced durability

- Finish: Hot-Dip Galvanised to BS EN ISO 1461:2009

- Slot Sizes: Available with standard slot dimensions for flexibility

- Lengths: Standard and custom lengths available

- Load Capacity: Suitable for heavy-duty and high-load applications

- Installation: Compatible with a wide range of fasteners, bolts, and accessories

Industries Using Back to Back Slotted Channel

- Construction: Supports structural frameworks, industrial shelves, and equipment racks.

- Electrical Installations: Organizes cable management systems and secures conduits.

- Mechanical Engineering: Provides durable mounting solutions for machinery and industrial equipment.

- HVAC: Supports ductwork, air conditioning units, and ventilation systems.

- Plumbing: Stabilizes large-diameter pipes and supports pipe brackets.

Why Choose Our Back to Back Slotted Channel?

Flexibility and Versatility

The slotted design offers incredible flexibility, allowing for quick and easy adjustments during installation. This feature is perfect for projects that require components to be repositioned or customized on the job site.

High Load Capacity and Durability

By combining two channels in a back-to-back format, this solution ensures that even the heaviest loads can be supported. Its robust design is ideal for high-stress applications, ensuring the channel remains stable under pressure.

Corrosion Resistance for Long-Term Use

The Hot-Dip Galvanised finish provides long-term resistance to rust and corrosion, ensuring that the channel performs reliably over time, even in harsh outdoor environments.

Conclusion

The Back to Back Slotted Channel is a highly versatile and durable component that offers enhanced strength and flexibility for a variety of industrial applications. From supporting heavy pipes to organizing electrical systems, this product’s slotted design ensures easy adjustments and secure installations. With a Hot-Dip Galvanised finish for maximum protection against corrosion, you can trust this channel for long-lasting performance in both indoor and outdoor environments.

Invest in the Back to Back Slotted Channel for your next project and enjoy the benefits of a robust, flexible, and corrosion-resistant solution that meets all your structural support needs.

Showing all 2 results

Showing all 2 results