Back to Back Plain Channel: A Durable Solution for Heavy-Duty Support

What is Back to Back Plain Channel?

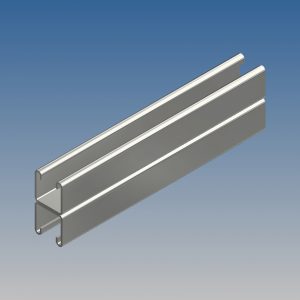

Back to Back Plain Channel is a versatile and robust structural support component widely used in industrial, mechanical, and construction projects. This configuration involves two plain channels connected back-to-back to create a stronger, more stable system capable of handling heavier loads. The design offers maximum support for various applications, including pipework, cable management, electrical installations, and HVAC systems.

Key Features of Back to Back Plain Channel

Enhanced Strength for Heavy-Duty Applications

One of the primary advantages of the Back to Back Plain Channel is its exceptional load-bearing capacity. By joining two channels, this system distributes weight more evenly, making it ideal for applications that require additional strength, such as:

- Pipe and Duct Supports: Provides excellent support for industrial piping, ductwork, and HVAC systems.

- Framing Systems: Commonly used in the construction of structural frameworks, shelving, and partitions.

- Cable Management: Helps secure and organize cable trays and conduits in electrical installations.

Smooth, Plain Channel Design

Unlike slotted channels, Back to Back Plain Channels do not feature pre-punched holes or slots. This smooth design allows for a more flexible installation, as holes can be drilled according to specific project requirements. It also provides a cleaner, more aesthetically pleasing look, particularly in visible installations.

Corrosion-Resistant Hot-Dip Galvanised Finish

Our Back to Back Plain Channels are available with a Hot-Dip Galvanised finish to ensure superior protection against rust and corrosion. This makes them suitable for both indoor and outdoor use, as they can withstand harsh environmental conditions. The finish complies with BS EN ISO 1461:2009 standards, ensuring long-lasting performance in even the most demanding environments.

Applications of Back to Back Plain Channel

Pipe Support Systems

The Back to Back Plain Channel is frequently used in pipe support systems, where it helps stabilize large-diameter pipes used in industrial plumbing, HVAC, and fire sprinkler systems. The back-to-back configuration provides extra stability, ensuring that pipes remain securely in place, even under heavy loads.

Electrical Installations

In electrical systems, these channels are often used to support and mount cable trays, conduits, and other electrical infrastructure. Their strength and adaptability make them a popular choice for organizing and securing electrical systems in both commercial and industrial settings.

Custom Framing Solutions

The Back to Back Plain Channel is ideal for constructing custom framing solutions. Whether used for building shelves, partitions, or equipment mounts, its heavy-duty design offers reliability and flexibility, allowing contractors to create secure and long-lasting structures.

HVAC Systems

When supporting HVAC systems, the Back to Back Plain Channel provides the strength needed to secure ductwork, air conditioning units, and ventilation equipment. Its robust design makes it an excellent choice for environments where vibration and movement could otherwise compromise the stability of the installation.

Technical Specifications

- Material: High-grade steel for maximum durability

- Finish: Hot-Dip Galvanised to BS EN ISO 1461:2009

- Lengths: Available in standard and custom lengths

- Channel Width: Common sizes include 41x21mm, 41x41mm, and more

- Load Capacity: Suitable for heavy-duty applications

- Installation: Plain channel design allows for custom drilling based on project needs

Why Choose Back to Back Plain Channel?

Strength and Stability

The Back to Back Plain Channel provides significantly more strength than a single channel. This added stability makes it the ideal choice for applications where safety and durability are top priorities.

Corrosion Resistance

The Hot-Dip Galvanised finish ensures that the channel remains resistant to rust and corrosion, extending its lifespan even in outdoor or chemically harsh environments.

Versatility

With the plain channel design, holes can be drilled based on specific project requirements. This flexibility makes the Back to Back Plain Channel highly adaptable for a range of uses, including pipe supports, framing systems, and cable management.

Custom Sizes and Options

The Back to Back Plain Channel can be tailored to meet the specific needs of your project. Whether you need a particular length, width, or custom finish, we can provide the perfect solution to ensure a successful installation.

Easy to Install

Compatible with a wide range of fixings and mounting accessories, the Back to Back Plain Channel can be quickly and easily installed. The modular nature of the design allows for seamless integration with other components, such as strut nuts, brackets, and clamps.

Common Industries Using Back to Back Plain Channel

- Construction: Widely used in framing systems, shelving, and structural supports.

- Mechanical Engineering: Provides stable support for machinery and equipment.

- Electrical Installations: Ideal for securing conduits, cable trays, and other electrical infrastructure.

- HVAC Systems: Used to mount and support ductwork, air conditioning units, and ventilation equipment.

Conclusion

The Back to Back Plain Channel is an essential component in projects that require extra strength, durability, and flexibility. Its smooth, plain design allows for custom drilling, making it suitable for a wide range of applications, from pipe supports to custom framing. With a Hot-Dip Galvanised finish ensuring long-lasting protection against rust and corrosion, this channel system is perfect for both indoor and outdoor installations.

Invest in Back to Back Plain Channels to ensure your projects are built on a foundation of strength, reliability, and adaptability.

Showing all 2 results

Showing all 2 results