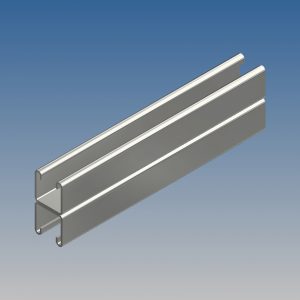

Back to Back Channel: The Ultimate Structural Support Solution

Introduction to Back to Back Channel Systems

The Back to Back Channel is an essential component used in a variety of construction, industrial, and mechanical applications. Known for its durability and flexibility, this channel system consists of two channels welded or bolted together in a back-to-back configuration, providing enhanced strength and load-bearing capacity. Whether you’re working on supporting pipework, cable trays, or creating framing systems, the back-to-back channel is an ideal choice for projects requiring heavy-duty structural support.

Key Features of Back to Back Channel

Exceptional Load-Bearing Capacity

The Back to Back Channel is designed to provide superior support in applications that require high load-bearing capacity. This makes it ideal for projects such as supporting electrical conduit systems, pipework, air conditioning units, and even structural frameworks. The double channel design distributes weight more evenly, allowing for heavier loads without compromising stability or safety.

Versatile Applications in Construction and Mechanical Installations

From construction sites to industrial facilities, Back to Back Channels are versatile components used in a wide range of applications. Some of the most common uses include:

- Cable Management: The channel system is often used to support cable trays, keeping electrical systems organized and safely mounted.

- Pipe Supports: It provides stable, long-lasting support for HVAC, plumbing, and industrial piping systems.

- Framing Systems: When used in conjunction with other Unistrut or strut channel components, the back to back channel helps create custom framing solutions for equipment mounting, partitions, and shelving systems.

Hot-Dip Galvanised for Corrosion Resistance

Our Back to Back Channels are available with a Hot-Dip Galvanised finish, providing outstanding protection against corrosion and rust. The galvanisation process ensures that the channels can withstand exposure to moisture, chemicals, and extreme temperatures, making them suitable for both indoor and outdoor use. Complying with BS EN ISO 1461:2009 standards, the galvanised finish prolongs the life of the channel and ensures a reliable solution in harsh environments.

Custom Lengths and Sizes

Back to Back Channels come in various lengths, widths, and hole patterns to suit different project requirements. Whether you need slotted channels for easier adjustability or pre-cut lengths to meet specific structural needs, the versatility of back to back channels makes it easy to find the perfect solution for your project.

Common Applications of Back to Back Channel

Industrial Pipe Support Systems

In industrial facilities, the Back to Back Channel is often used to support large diameter pipes in systems such as water, gas, and oil distribution. By providing a solid structural base, it helps prevent pipes from sagging or shifting, ensuring a safe and secure installation.

Electrical Conduit Systems

In electrical systems, back to back channels provide a stable platform for mounting and securing conduits, cable trays, and junction boxes. The heavy-duty design ensures that electrical infrastructure remains organized and safe, reducing the risk of damage or interference.

HVAC Installations

For HVAC systems, the back to back channel is essential for supporting ductwork, ventilation equipment, and air conditioning units. Its robust design ensures that all components remain securely in place, even in environments with significant vibration or movement.

Construction Framework

In construction projects, Back to Back Channels are often used as part of structural frameworks, creating reliable support for shelving systems, partitions, and other custom structures. The adjustable nature of the slotted channels allows for easy assembly and modification, making it a popular choice for builders and contractors.

Technical Specifications

- Material: High-quality steel

- Finish: Hot-Dip Galvanised to BS EN ISO 1461:2009

- Lengths Available: Custom lengths available upon request

- Channel Width: Standard widths such as 41x21mm, 41x41mm, and more, depending on project requirements

- Hole Type: Slotted or plain

- Mounting Type: Back-to-back configuration for enhanced load-bearing capacity

- Applications: Pipe supports, cable management, structural framing, HVAC, and more

Advantages of Using Back to Back Channel

Increased Load Capacity

The back-to-back configuration doubles the strength and load-bearing capacity compared to single channels. This makes it ideal for heavy-duty applications where safety and stability are top priorities.

Corrosion-Resistant Finish

The Hot-Dip Galvanised finish ensures that the back to back channel is resistant to corrosion, rust, and environmental damage, ensuring long-term performance in outdoor installations or in chemically harsh environments.

Flexible and Customizable

Available in various sizes, lengths, and hole patterns, Back to Back Channels can be easily customized to meet specific installation needs. Whether it’s a commercial project or a residential one, these channels offer flexibility and adaptability.

Easy Installation

Back to Back Channels are compatible with a wide range of fixings, including channel nuts, brackets, bolts, and clamps, making installation quick and easy. Their modular design allows for future adjustments or expansions, saving time and resources.

Why Choose Our Back to Back Channel?

- Durability: Manufactured to the highest standards using premium-quality steel, ensuring long-lasting strength and reliability.

- Corrosion Resistance: The galvanised finish protects the channel from rust and wear, even in challenging environments.

- Versatility: Ideal for various applications, including pipework, cable trays, HVAC systems, and structural framing.

- Custom Options: Choose from a range of sizes, lengths, and finishes to suit the specific needs of your project.

Conclusion

The Back to Back Channel is the go-to solution for professionals in need of a strong, versatile, and durable support system. With its enhanced load-bearing capacity, corrosion-resistant finish, and adaptability, this channel system is perfect for pipe supports, cable management, HVAC installations, and more. Invest in Back to Back Channels to ensure your projects are built on a foundation of strength and reliability.

Showing all 2 results

Showing all 2 results