Strut and Channel

Understanding Strut and Channel: Essential Components for Construction and Electrical Applications

Strut and channel systems, often known by various manufacturer trade names, are standardized structural solutions widely utilized in the construction and electrical industries. These versatile systems provide essential light structural support, making them ideal for mounting wiring, plumbing, and mechanical components, such as air conditioning and ventilation systems.

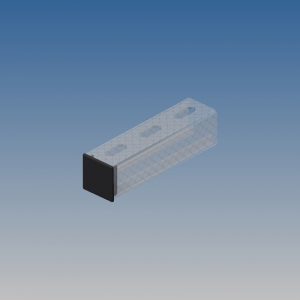

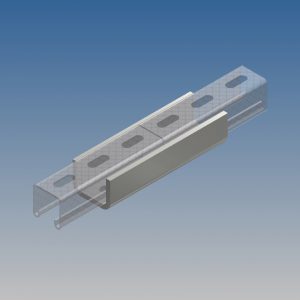

What is Strut?

Strut is typically fabricated from metal sheets that are folded into an open channel shape, featuring inward-curving lips. This design not only enhances stiffness but also serves as a mounting point for interconnecting components. The base of strut channels usually includes pre-drilled holes, which facilitate easy fastening to underlying building structures and allow for various interconnections.

Advantages of Strut Channels in Construction

One of the primary benefits of using strut channels is their versatility and ease of assembly. A wide range of specialized fasteners and bolts are available, allowing for rapid and straightforward connections between lengths of strut and other components. This efficient assembly process requires only basic tools and moderately trained labor, which significantly reduces labor costs across many applications.

Additionally, strut channel installations can be easily modified or expanded as needs change. This adaptability is a stark contrast to traditional alternatives, which often involve custom fabrication using steel bars and other commodity materials. Such methods typically require welding, extensive drilling, and bolting, lacking the efficiency and flexibility offered by strut channels.

Applications of Strut and Channel Systems

Strut and channel systems are primarily used to mount, brace, support, and connect lightweight structural loads in building construction. Common applications include:

- Piping Systems: Securing water and gas pipes to ensure safe and efficient transportation.

- Electrical and Data Wiring: Providing stable support for electrical conduits, cables, and data lines.

- Mechanical Systems: Supporting HVAC installations, ventilation ducts, and other mechanical components.

Conclusion

In summary, strut and channel systems are indispensable components in modern construction and electrical applications. Their ease of assembly, versatility, and ability to adapt to changing needs make them a preferred choice for many professionals in the industry. Whether you’re mounting lightweight structural loads or connecting mechanical systems, strut channels provide a reliable and cost-effective solution.

For more information on our range of strut and channel products or to get expert guidance on your project, feel free to contact our knowledgeable Sales Team. Investing in quality strut systems will enhance your construction projects and streamline your operations.