Strut and Channel

Strut and Channel are often referred to colloquially by one of several manufacturer trade names, is a standardized formed structural system used in the construction and electrical industries for light structural support, often for supporting wiring, plumbing, or mechanical components such as air conditioning or ventilation systems.

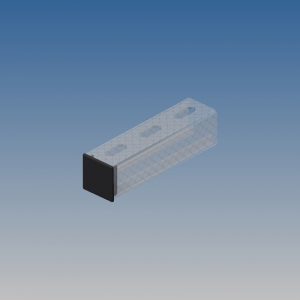

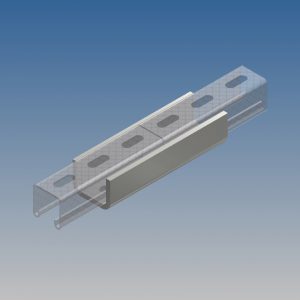

Strut is generally formed from a metal sheet, folded over into an open channel shape with inwards-curving lips to provide additional stiffness and as a location to mount interconnecting components. Struts usually have holes of some sort in the base to facilitate interconnection or fastening strut to underlying building structures.

One of the main advantages of strut channels in construction is that there are many options available for rapidly and easily connecting lengths together and other items to the strut channel, using various specialised strut specific fasteners and bolts. They can be assembled very rapidly with minimal tools and only moderately trained labour, which reduces costs significantly in many applications.

A strut channel installation also can often be modified or added to relatively easily if required. The only alternative to strut channels for most applications is custom fabrication using steel bar and other commodity components, requiring welding or extensive drilling and bolting, which has none of the above advantages.

These are used to mount, brace, support, and connect lightweight structural loads in building constructions. These can include pipes, electrical and data wire, mechanical systems such as ventilation, air conditioning, and other mechanical systems.